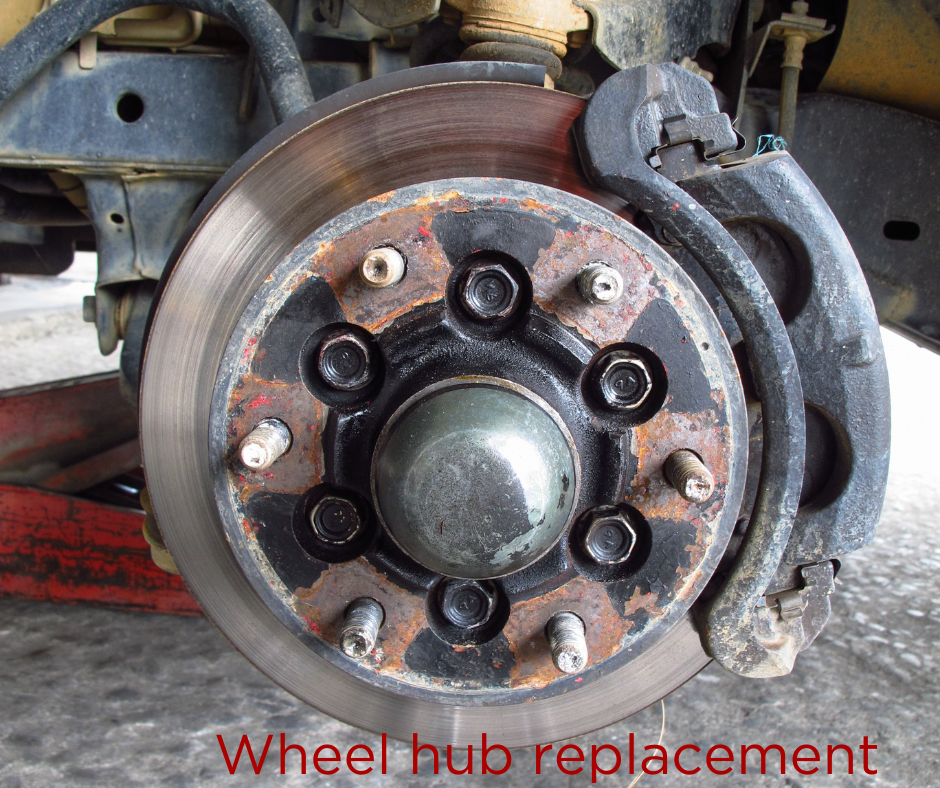

In Kenya, where road conditions can be challenging, proper hub bearing maintenance is crucial to ensure smooth vehicle operation and safety. A worn-out hub bearing can place you and your passengers at risk of accidents. In this article, we will explore the hub bearing replacement process, covering preparation, tools, and the necessary safety precautions. Read on to find out.

Before diving into the replacement process, thorough preparation is essential. This includes:

The following tools and equipment are typically required for hub bearing replacement:

Note: Depending on your vehicle, additional tools might be necessary.

It’s essential to prioritize safety throughout the hub bearing replacement process. Here are some safety precautions to consider:

The hub bearing replacement procedure will depend on your type of vehicle. For instance, trucks like NQR, FH, Fuso, Tata, and Toyota Hiace (matatu) may require more advanced procedures compared to regular cars. Popular cars include Probox, Toyota Premio, Toyota Fielder, etc.

Here are the general steps for replacing hub bearings.

Hub bearing replacement is a critical maintenance task that you shouldn’t overlook. By following the replacement process outlined in this article, you can ensure smooth operation, safety, and prolonged lifespan of your hub bearings.

However, hub bearing replacement can be a complex task, especially for larger vehicles. If you are not confident in your mechanical skills or the specific requirements for your car, don’t hesitate to seek help from a qualified mechanic. For more insights regarding hub bearings replacement, don’t hesitate to contact us today.

WhatsApp us